Discover Ceramic Coating Denver: Boost Your Automobile's Look and Security

Discover Ceramic Coating Denver: Boost Your Automobile's Look and Security

Blog Article

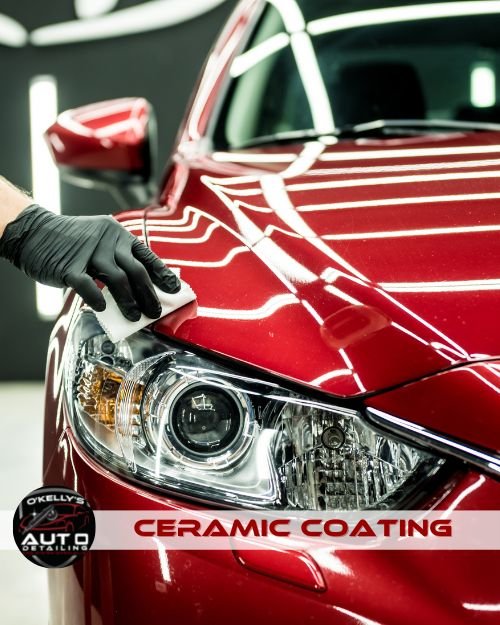

Exploring Ceramic Covering: A Detailed Check Out the Application Refine and Secret Advantages

Worldwide of automobile care, ceramic layer has gained significant traction for its capacity to supply a safety layer that enhances the look and long life of different surface areas. Beyond the allure of a glossy coating, the application procedure and advantages of ceramic covering are diverse. From recognizing the careful prep work needed prior to application to diving right into the step-by-step details of the procedure, there is a riches of information to unload. Moreover, exploring the subtleties of long-lasting toughness and the considerations in between DIY application and expert solutions can supply useful insights for those considering this advanced form of protection for their vehicles.

Benefits of Ceramic Covering

Undoubtedly, one of one of the most compelling aspects of ceramic coating is its unequaled ability to offer resilient protection to different surfaces. Ceramic covering develops a solid and long lasting bond with the surface area it is applied to, creating a protective layer that can stand up to environmental stressors such as UV rays, chemicals, bird droppings, and minor scratches. This safety layer functions as a shield, maintaining the stability of the surface beneath for an extended duration.

In addition, ceramic finishings are extremely hydrophobic, indicating they repel water and avoid pollutants from bonding to the surface area. This hydrophobic nature not just makes surfaces easier to clean but additionally keeps a glossy surface, improving the aesthetic appeal of automobiles, structures, or various other covered things.

Getting Ready For Application

To make certain an effective application of ceramic coating, extensive prep work of the surface is important. The primary step in preparing for the application of ceramic finishing is to completely clean the surface area that will be treated. This entails cleaning the surface to remove any dust, particles, or deposits that could conflict with the bonding of the finish. After cleansing, it is critical to decontaminate the surface area to get rid of any remaining contaminations such as results, grease, or tar particles.

Once the surface is tidy and complimentary of impurities, the next step is paint correction, if essential. This includes getting rid of any kind of swirl marks, scrapes, or flaws from the paintwork to guarantee a flawless and smooth surface for the ceramic layer to stick to. After the paint correction process, the surface area must be wiped down with isopropyl alcohol to remove any kind of sprucing up oils or deposits that may exist.

Step-by-Step Application Process

The application procedure of ceramic covering entails an organized series of steps to make sure a specific and sturdy finish on the dealt with surface area (ceramic coating denver). To start with, the surface needs to be completely cleansed and decontaminated to eliminate any kind of dirt, grease, or residue that could disrupt the bonding of the ceramic finishing. This is normally done via a precise cleaning and drying out process, followed by claying to eliminate ingrained pollutants

After the surface area is tidy, the ceramic finish is used making use of an applicator pad or towel. The covering is spread out evenly in a cross-hatch pattern to ensure full coverage. It is vital to work in little sections to avoid the product from drying out prematurely, which can cause irregular application.

When the ceramic finish is applied, it needs to treat for a specific duration to bond with the surface area correctly. This curing time differs depending upon the item made use of, but it is crucial to enable sufficient time for the covering to create a long lasting safety layer. Lastly, an extensive evaluation is conducted to make sure the finishing has actually been used uniformly, offering the wanted degree of security and improvement to the surface.

Recognizing Long-Term Resilience

In analyzing the durability of ceramic layers, it is vital to consider various variables that add to their enduring safety buildings. One essential facet affecting long-lasting durability is the preparation of the surface prior to the ceramic covering application. Proper go now cleaning, decontamination, and paint adjustment make sure a smooth and clean surface for the coating to abide by efficiently, boosting its durability. Furthermore, the top quality of the ceramic coating item used plays a substantial function in establishing for how long the finish will last. Premium ceramic layers developed with innovative technology and sturdy active ingredients have a tendency to provide extensive security compared to lower-grade choices.

In addition, the proficiency of the applicator and the application procedure itself are important variables impacting the longevity of the ceramic coating. A professional application following the maker's standards ensures even protection and correct bonding, optimizing the finishing's life-span. In addition, routine upkeep such as mild washing and preventing severe chemicals or rough cleansing approaches can help lengthen the effectiveness of the ceramic covering, guaranteeing lasting defense for your vehicle's surface.

Comparing Do It Yourself Vs. Expert Application

When considering the application of ceramic layers, assessing the distinctions between diy (DIY) and expert application methods is crucial for accomplishing optimal outcomes. DIY ceramic layer sets are readily available and can be appealing due to their reduced cost compared to employing a professional. Nonetheless, do it yourself application requires precise preparation, including paint improvement and surface decontamination, to ensure correct attachment and longevity of the finishing. Without the essential experience and equipment, do it yourself enthusiasts may have a hard time review to accomplish a perfect surface and lasting defense.

On the various other hand, specialist ceramic layer application offers several advantages. Experts are learnt the appropriate application strategies, making certain a consistent finishing thickness and insurance coverage. They additionally have accessibility to better ceramic coverings that may give far better durability and efficiency. Additionally, specialist installers commonly provide service warranties on their work, supplying added comfort to lorry proprietors. While the initial expense of expert application may be higher, the competence, top quality of materials, and long-lasting advantages typically exceed the ahead of time financial investment. Eventually, the choice between a DIY or expert application will rely on individual ability degree, budget, and preferred result.

Conclusion

In conclusion, ceramic finishing uses various advantages such as enhanced protection, improved look, and simplicity of maintenance for numerous surfaces. Inevitably, ceramic layer verifies to be a rewarding financial investment for those looking to extend the life expectancy and looks of their belongings.

To make certain an effective application of ceramic coating, comprehensive preparation of the surface area is essential.The application procedure of ceramic covering entails a methodical series of actions to make certain a long lasting and precise finish on the dealt with surface. One crucial aspect affecting long-lasting sturdiness is the preparation of the surface area prior to the ceramic layer application. Furthermore, the top quality of the ceramic finishing item used plays a significant duty in establishing just how long the finishing will certainly last.When considering the application of ceramic coverings, evaluating the differences in between do-it-yourself (DIY) and professional application approaches is important More about the author for achieving optimum outcomes.

Report this page